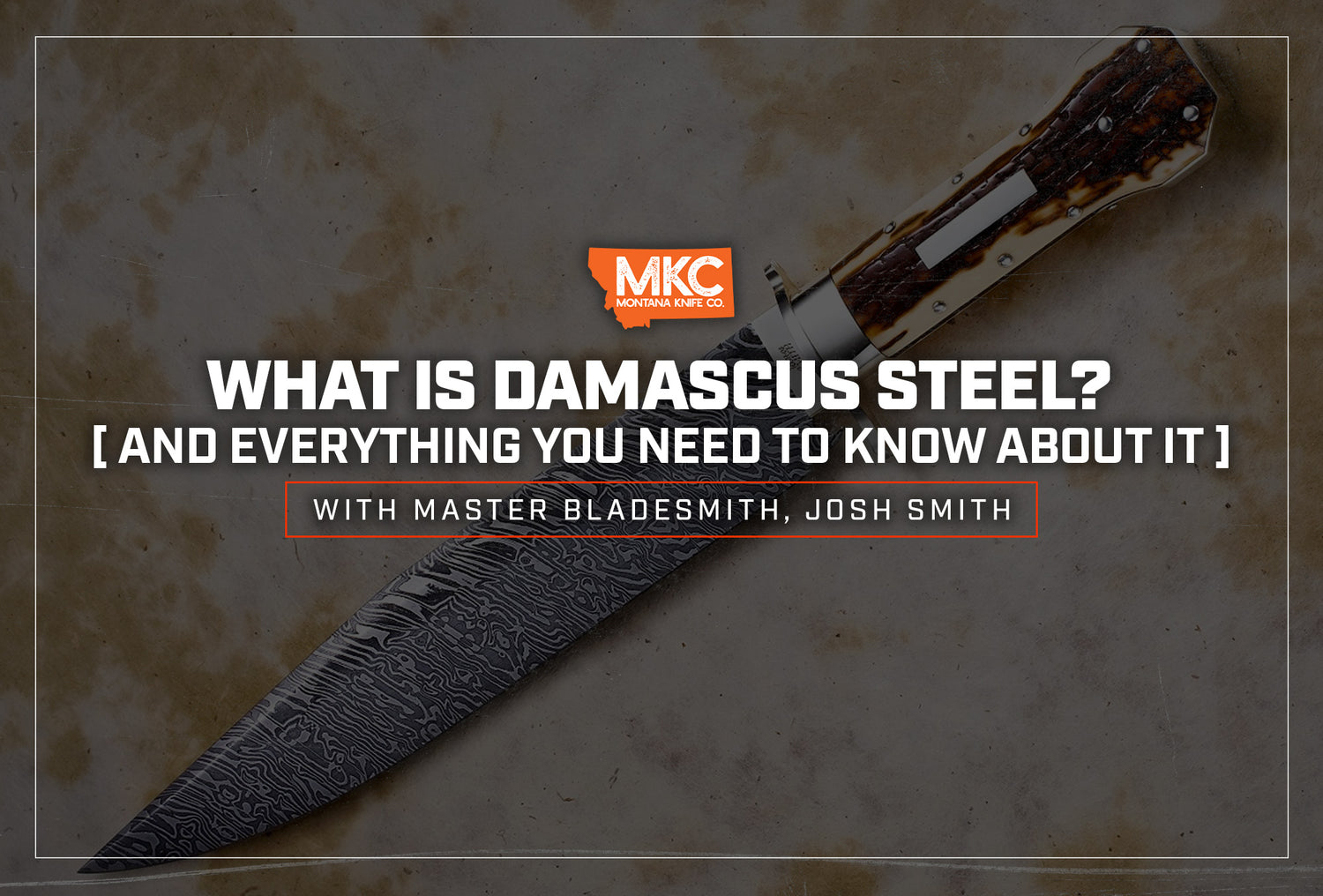

What is Damascus steel?

Damascus steel is one solid piece of steel made from layering two different alloys — 1080 high-carbon steel and 15N20 carbon steel, for instance.

You can’t make Damascus steel by combining two pieces of the same alloy. That would be like stacking red Play-Doh on top of red Play-Doh — you just end up with red Play-Doh.

But when you stack red Play-Doh on top of yellow Play-Doh, you end up with different layers and colors, just like the different layers you’d see in a Damascus steel blade. You need to combine a high-carbon content steel and a high nickel content steel to create a nice contrast.

I started working with Damascus steel as a teenager, meaning I’ve been working with it for over 25 years to date. In fact, in 2000, I won the “Best Damascus Knife” award at Blade Show Atlanta, the world’s largest knife show.

Needless to say, I know a thing or two about Damascus steel — and I’m packing all my knowledge into this blog post to help you understand it, too.

Why Is Damascus Steel So Expensive?

It’s no secret that Damascus steel isn’t cheap. That’s because it takes a lot of time and manpower to make.

It also takes a lot of experience and trial and error to become proficient at making Damascus steel. So, when you purchase a Damascus steel blade, you’re ultimately paying for the maker’s years of expertise.

How Is Damascus Steel Made?

Damascus steel is made by heating steel to a temperature of ~2,300°F (don’t try this at home, kids!) and then applying pressure to the steel under a hydraulic press or hammer. At that temperature, two pieces of steel will weld to each other to create one solid block.

The multiple layers of alternating steel are folded over and over to create even more layers. Often, you can make 10 normal knives in the amount of time it takes to forge one Damascus knife, depending on how complicated the pattern is.

How Strong Is Damascus Steel Compared to Other Popular Steels?

Damascus steel is no stronger or weaker than the steel it’s made from.

For example, if you make Damascus steel from two strong alloys, you’ll create a strong Damascus steel knife. But if you made Damascus steel from mild steel and nickel, you’ll end up with a soft and — from a knife usability perspective — useless piece of steel.

Damascus steel only refers to the way the steel looks — not how it performs. If heat-treated correctly, Damascus steel offers the same performance as the alloys you choose to include.

Can You Make Damascus Steel From Any Steel?

No, you can’t make Damascus steel from just any steel.

Certain steels don’t react well to forging, and not all steel welds. Steel’s ability to forge and weld depends on the alloys it’s made from.

For example, you can’t use MagnaCut steel to create Damascus steel. You can, however, use 1080 and 15N20 high-carbon steel, which is what we use to make the Topo Damascus Speedgoat and our other Damascus steel blades.

Do I Need to Sharpen Damascus Steel Differently Than Other Types of Steel?

You don’t have to follow any particular protocol to sharpen your Damascus steel knife. Sharpen it the same way you would sharpen any other high-quality blade from Montana Knife Company.

How Can You Tell Real Damascus Steel From Fakes?

There are several Damascus blades sold through online retailers, like Amazon, that are either fake or poor quality. Usually, these knives are made with a laser and cost less than $100.

If you’re looking for a high-quality, authentic Damascus knife, you can’t go wrong with an American-made blade, which will cost several hundred dollars.

What Is Damascus Steel? Final Thoughts

If you’re looking to invest in a Damascus blade, ask whether it’s made from stainless steel or carbon steel. If it’s made with carbon steel, use blade wax to keep it in great shape like you would a regular carbon steel blade.

If you were wondering, “What is Damascus steel?”, I hope this post answered some of your pressing questions.

by Josh Smith, Master Bladesmith and Founder of Montana Knife Company